一:Graphene oxide paste:

Item No.: MC-18

1、Performance

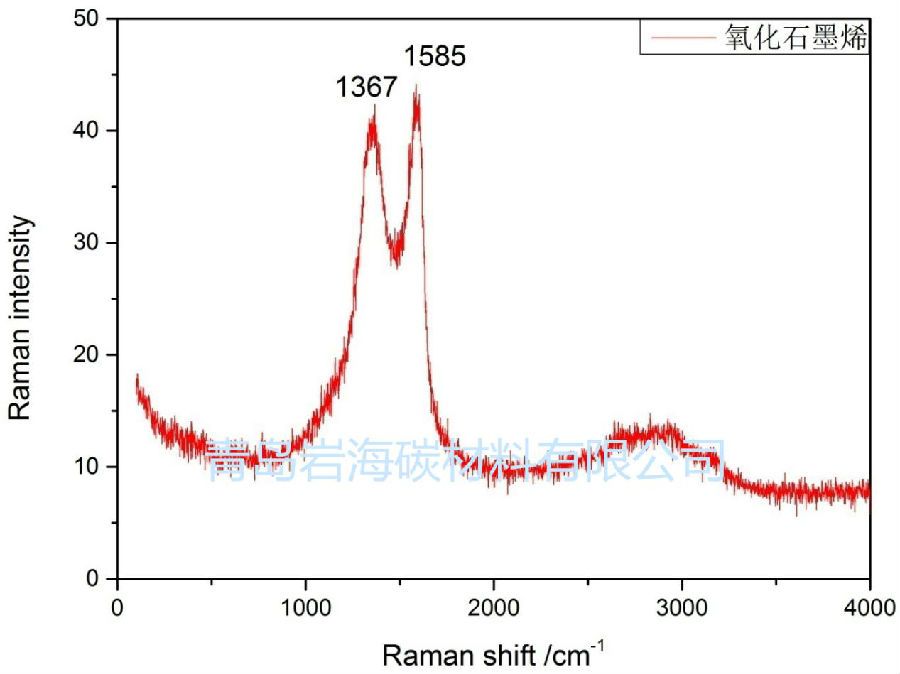

(1)Has oxygen-containing functional groups such as rich hydroxyl, carboxyl and epoxy groups

(2)It is easy to graft modification and can be combined with the composite in situ, which endows the composite with conductive, thermal, reinforcing, flame retardant, antibacterial and bacteriostasis properties.

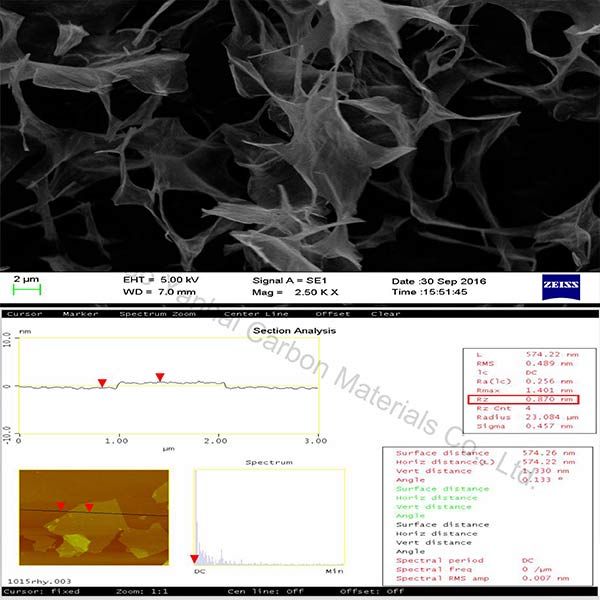

(3)Easy to peel into stable graphene oxide dispersion and easy to film.

2、Application

It can be used in the field of rubber, plastic, resin, fiber and other polymer composites, and can also be used in the composite of lithium electric anode and cathode materials, graphene thermal conductive film, catalyst loading.

3、Technical indicators

Item No. | parameter | ||||||

Appearance | Solid Content(%) | pH | viscosity(Pa·S) | Carbon mass fraction (%) | Carbon oxide molar ratio O/C | Sulfur content(%) | |

MC-18

| Brown yellow (brown) to black paste | 43 ± 5 | 1.5-1.8 | 1.5-5.0 | 47±5 | 0.6±0.1 | ≤4.0 |

二:Graphene oxide powders

1、Production Introduction

Graphene oxide flakes are a product of graphite powder after chemical oxidation and stripping. It has the properties of polymer, colloid, film, and amphoteric molecules and it has good dispersion in water.

三:Operational disposal and storage

Operators should wear suitable protective clothing and protective gloves; avoid direct contact with the skin, once enter the eyes, immediately wash with a large amount of water. Products should be stored in a cool, ventilated and dry environment, better storage in 20℃ environment. Keep away from fire and heat source and store separately with strong reducing agent and combustible material.